TAILORED EFFICIENCY

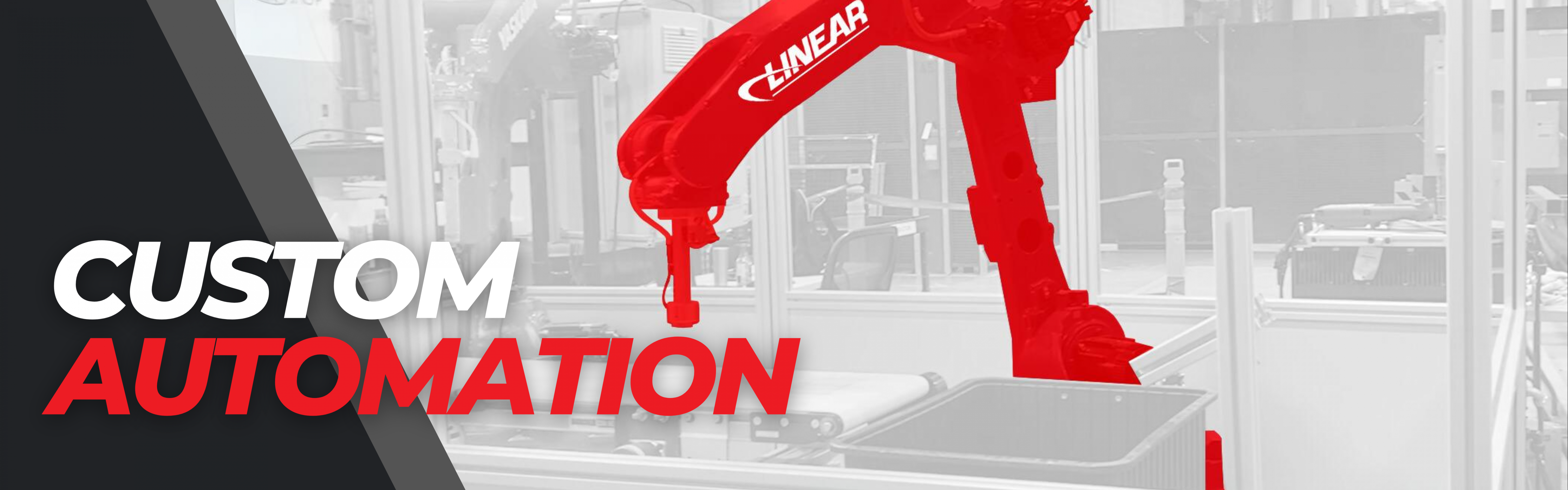

LINEAR AUTOMATION’S CUSTOM SOLUTIONS

TAILORED EFFICIENCY

In today’s rapidly evolving manufacturing landscape, companies face diverse challenges that demand innovative solutions. Linear Automation has become a beacon of tailored efficiency, offering bespoke automation solutions to address unique manufacturing needs. Linear Automation stands at the forefront of revolutionizing production processes through cutting-edge technology and personalized approaches.

UNDERSTANDING CUSTOMIZATION NEEDS

Every manufacturing environment has unique challenges, from product specifications to workflow complexities. At Linear Automation, we understand that a one-size-fits-all approach doesn’t work for metal forming automation. We take a consultative approach, thoroughly analyzing each client’s operations. By conducting detailed assessments and engaging in collaborative discussions, we gain valuable insights into the specific challenges and opportunities within the metal forming process. This allows us to tailor our automation solutions to meet the unique needs of each manufacturing environment.

BIN-PICKING

UNDERSTANDING CUSTOMIZATION NEEDS

Every manufacturing environment presents its own set of intricacies, ranging from product specifications to workflow intricacies. Linear Automation recognizes that a one-size-fits-all approach is inadequate in meeting these varied demands. Instead, the company adopts a consultative approach, delving deep into understanding the nuances of each client’s operations. Through comprehensive assessments and collaborative dialogues, Linear Automation gains insights into the specific challenges and opportunities within the manufacturing ecosystem.

BIN-PICKING

UNDERSTANDING CUSTOMIZATION NEEDS

Every manufacturing environment presents its own set of intricacies, ranging from product specifications to workflow intricacies. Linear Automation recognizes that a one-size-fits-all approach is inadequate in meeting these varied demands. Instead, the company adopts a consultative approach, delving deep into understanding the nuances of each client’s operations. Through comprehensive assessments and collaborative dialogues, Linear Automation gains insights into the specific challenges and opportunities within the manufacturing ecosystem.

BIN-PICKING

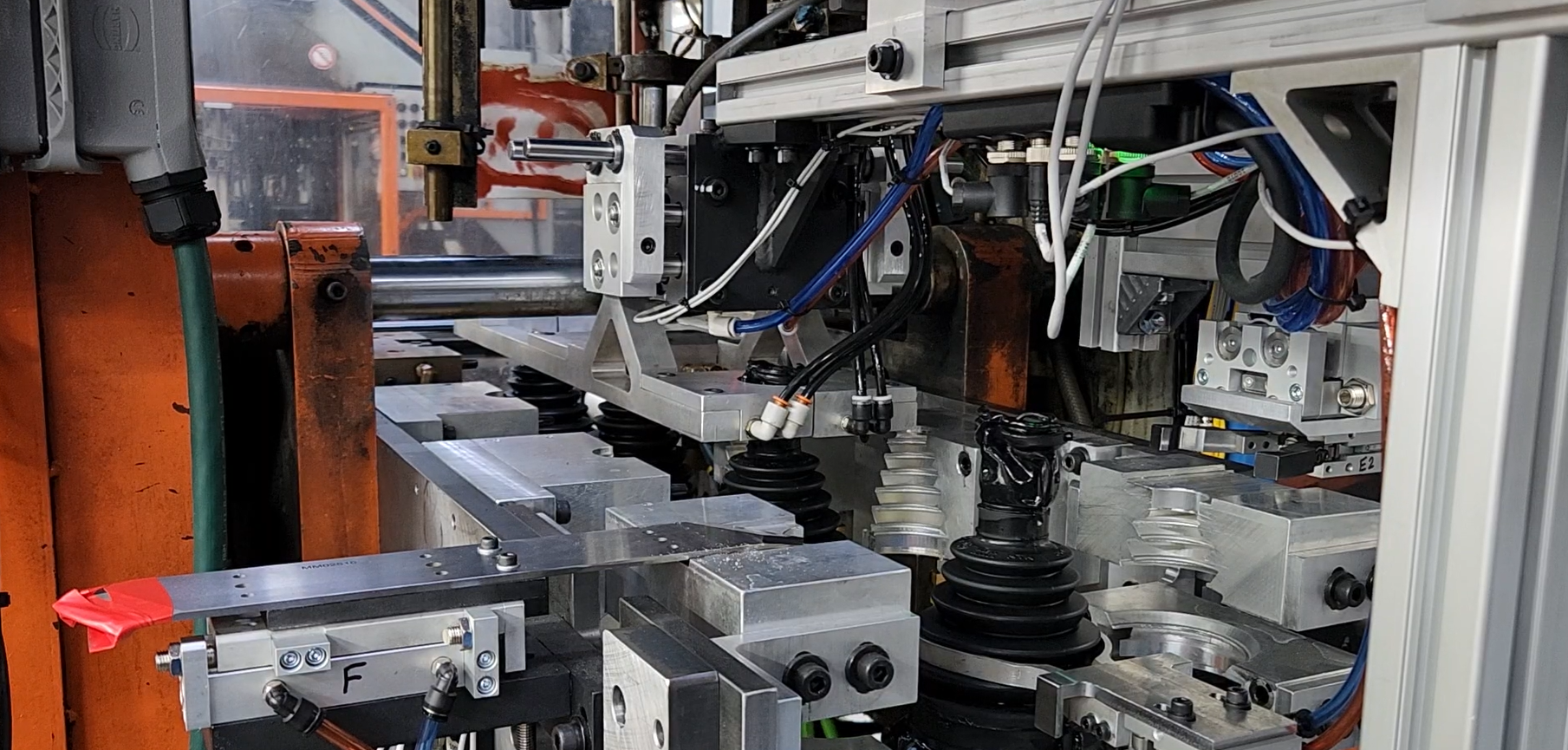

FORGING TRANSFER SYSTEM

DESIGNING TAILORED SOLUTIONS

Armed with a thorough understanding of client requirements, Linear Automation’s team of experts embarks on crafting customized solutions. Leveraging a diverse toolkit of technologies tailored to optimize efficiency, enhance productivity, and streamline operations. Whether it’s automating assembly lines, implementing quality control measures, or enhancing logistics processes, Linear Automation’s solutions are meticulously tailored to align with client objectives.

FORGING TRANSFER SYSTEM

DESIGNING TAILORED SOLUTIONS

Armed with a thorough understanding of client requirements, Linear Automation’s team of experts embarks on crafting customized solutions. Leveraging a diverse toolkit of technologies tailored to optimize efficiency, enhance productivity, and streamline operations. Whether it’s automating assembly lines, implementing quality control measures, or enhancing logistics processes, Linear Automation’s solutions are meticulously tailored to align with client objectives.

COMMITMENT TO INNOVATION & EFFICIENCY

In an era defined by rapid technological advancements and evolving market dynamics, Linear Automation’s custom solutions offer a beacon of innovation and efficiency for the manufacturing industry. By prioritizing collaboration, flexibility, and continuous improvement, the company empowers clients to overcome challenges, seize opportunities, and thrive in a competitive landscape. As manufacturing continues to evolve, Linear Automation remains committed to pioneering tailored solutions that redefine industry standards and drive sustainable success.

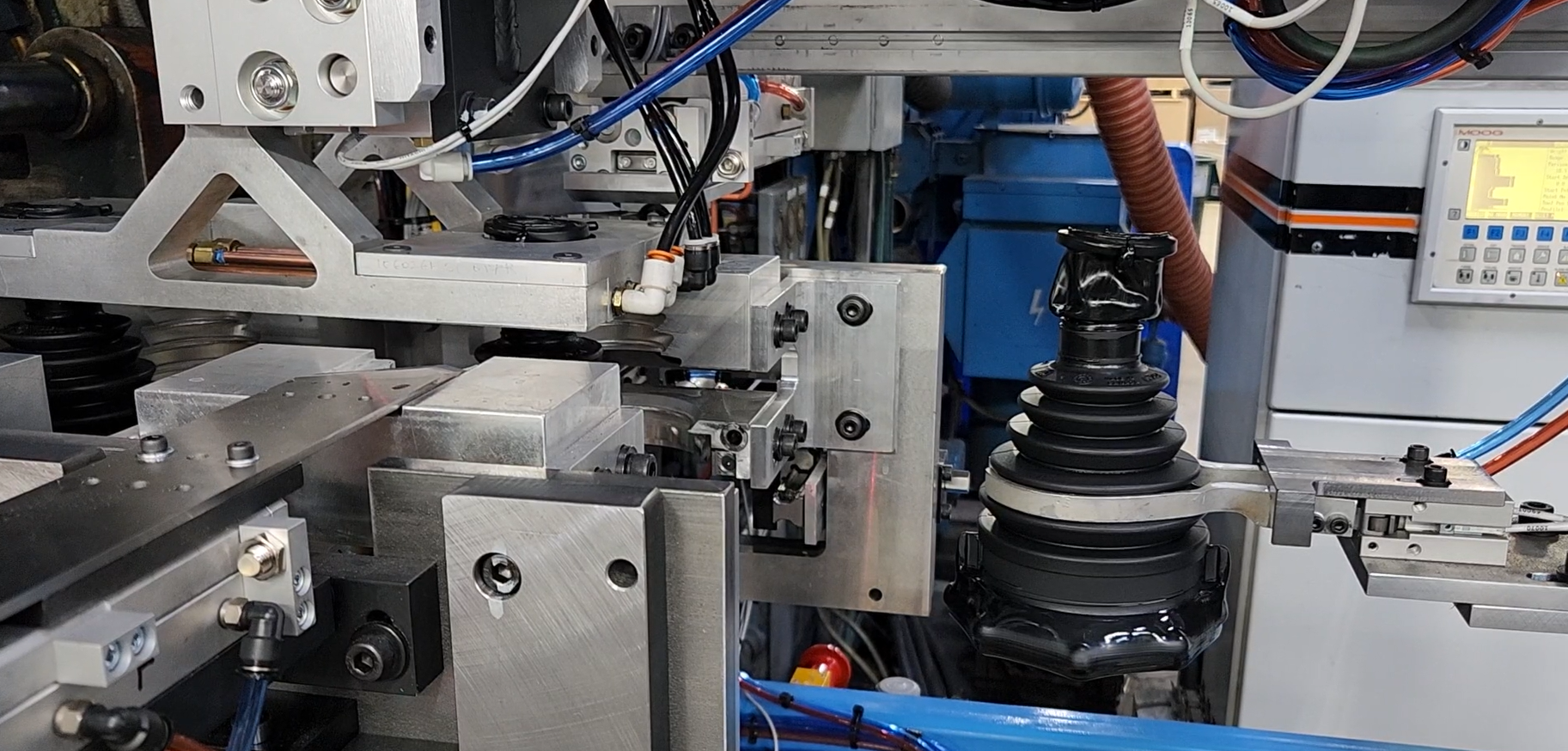

RUBBER CUTTER & TRANSFER

COMMITMENT TO INNOVATION & EFFICIENCY

In an era defined by rapid technological advancements and evolving market dynamics, Linear Automation’s custom solutions offer a beacon of innovation and efficiency for the manufacturing industry. By prioritizing collaboration, flexibility, and continuous improvement, the company empowers clients to overcome challenges, seize opportunities, and thrive in a competitive landscape. As manufacturing continues to evolve, Linear Automation remains committed to pioneering tailored solutions that redefine industry standards and drive sustainable success.

RUBBER CUTTER & TRANSFER

COMMITMENT TO INNOVATION & EFFICIENCY

In an era defined by rapid technological advancements and evolving market dynamics, Linear Automation’s custom solutions offer a beacon of innovation and efficiency for the manufacturing industry. By prioritizing collaboration, flexibility, and continuous improvement, the company empowers clients to overcome challenges, seize opportunities, and thrive in a competitive landscape. As manufacturing continues to evolve, Linear Automation remains committed to pioneering tailored solutions that redefine industry standards and drive sustainable success.

RUBBER CUTTER & TRANSFER

As manufacturing evolves, Linear Automation remains committed to pioneering tailored solutions that redefine industry standards and drive sustainable success.

Flexibility & Scalability

Linear Automation prioritizes adaptability to meet evolving manufacturing requirements. Our solutions are designed to be future-proof, accommodating changes in production volumes, product variations, and technological advancements. By focusing on flexibility, we ensure that your metal forming automation systems can easily adapt to future needs, enhancing efficiency and maintaining competitiveness in a rapidly changing industry.

Integration

At Linear Automation, we adopt a collaborative approach to ensure minimal disruption to your ongoing operations during the implementation of metal forming automation solutions. Our phased deployment strategy and rigorous testing protocols are designed to guarantee smooth integration with your existing infrastructure. By working closely with you, we ensure that our automation systems seamlessly blend into your current setup, minimizing downtime and enhancing operational efficiency.

Support

Linear Automation offers extensive support services following the implementation of your metal forming automation solutions. Our commitment includes ongoing monitoring, data analytics, and performance optimization to ensure that your systems operate at peak efficiency. By providing continuous support and insights, we help you maximize the effectiveness of your automation investment, ensuring long-term success and operational excellence.