24/7 Service & Support

Spare Parts Inventory

Expedited Parts Shipping

System Upgrades

Robot/PLC Programming

System Evaluations

Production Support

Remote Diagnostics

Annual Maintenance Contracts

24/7/365 COMPREHENSIVE SERVICE

At Linear Automation, our dedicated service team is available 24/7/365 to ensure your metal forming automation systems run smoothly year-round. We provide comprehensive support that includes upgrades, retrofits, and access to an extensive spare parts inventory. Our expertise extends to non-linear equipment support, ensuring that all aspects of your automation infrastructure are covered. Whether you need immediate assistance or are planning enhancements, our team is here to help. Contact us today to learn more about our exceptional service and how we can support your automation needs.

24/7/365 COMPREHENSIVE SERVICE

At Linear Automation, our dedicated service team is available 24/7/365 to ensure your metal forming automation systems run smoothly year-round. We provide comprehensive support that includes upgrades, retrofits, and access to an extensive spare parts inventory. Our expertise extends to non-linear equipment support, ensuring that all aspects of your automation infrastructure are covered. Whether you need immediate assistance or are planning enhancements, our team is here to help. Contact us today to learn more about our exceptional service and how we can support your automation needs.

24/7 Service & Support

Spare Parts Inventory

Expedited Parts Shipping

System Upgrades

Robot/PLC Programming

System Evaluations

Production Support

Remote Diagnostics

Annual

Maintenance Contracts

24/7/365 COMPREHENSIVE SERVICE

At Linear Automation, our dedicated service team is available 24/7/365 to ensure your metal forming automation systems run smoothly year-round. We provide comprehensive support that includes upgrades, retrofits, and access to an extensive spare parts inventory. Our expertise extends to non-linear equipment support, ensuring that all aspects of your automation infrastructure are covered. Whether you need immediate assistance or are planning enhancements, our team is here to help. Contact us today to learn more about our exceptional service and how we can support your automation needs.

Tonnage Calibration

Linear Automation offers field installation and tonnage calibration services for new or existing tonnage monitors.

LA-DiePro

The LA-DiePro System can help prevent costly die repairs and press downtime. With our simple to use system, misaligned parts, improper part/scrap ejection, misfeeds and material buckling can be detected before serious damage is done to the die or press. When a problem is detected the LA-DiePro System signals a stop to the press.

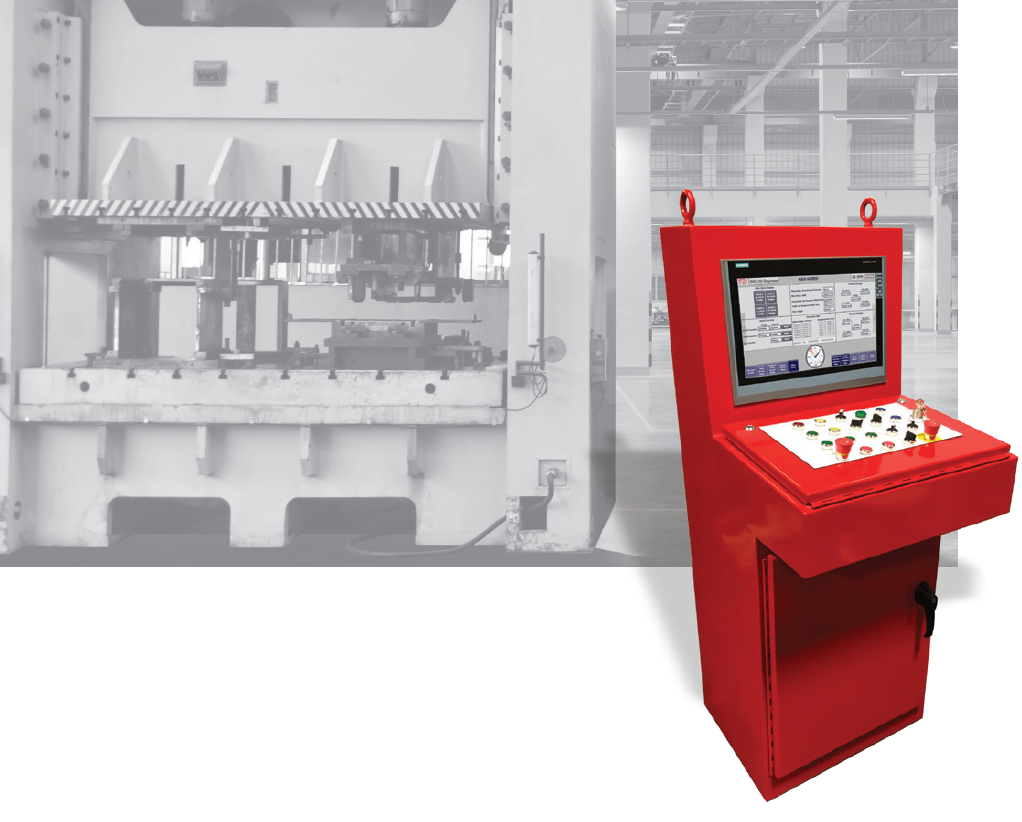

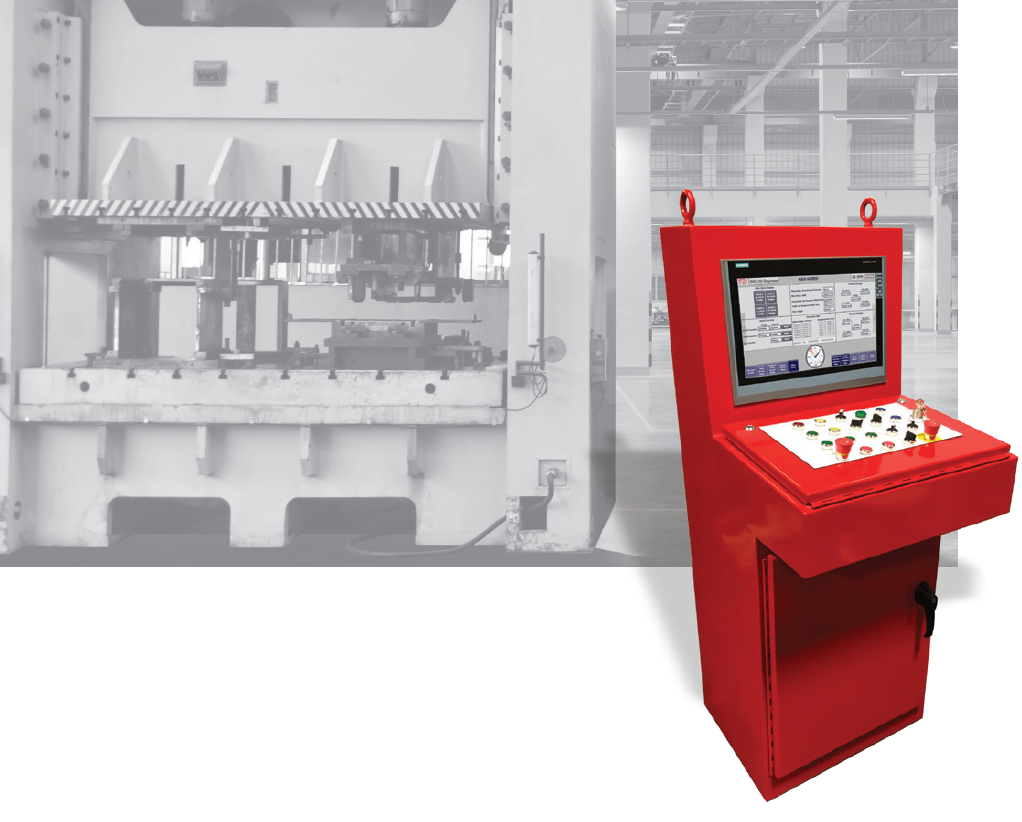

Press Control

LA-P-M is a quick, cost-effective retrofit solution to meet or exceed applicable safety standards (CSA, OSHA, ANSI). It easily interfaces with auxiliary equipment (transfer, feeder, de-stacker), is simple, clean, and intuitive to use, and is customizable to application-specific requirements.

Tonnage Calibration

Linear Automation offers field installation and tonnage calibration services for new or existing tonnage monitors.

LA-DiePro

The LA-DiePro System can help prevent costly die repairs and press downtime. With our simple to use system, misaligned parts, improper part/scrap ejection, misfeeds and material buckling can be detected before serious damage is done to the die or press. When a problem is detected the LA-DiePro System signals a stop to the press.

Press Control

LA-P-M is a quick, cost-effective retrofit solution to meet or exceed applicable safety standards (CSA, OSHA, ANSI). It easily interfaces with auxiliary equipment (transfer, feeder, de-stacker), is simple, clean, and intuitive to use, and is customizable to application-specific requirements.

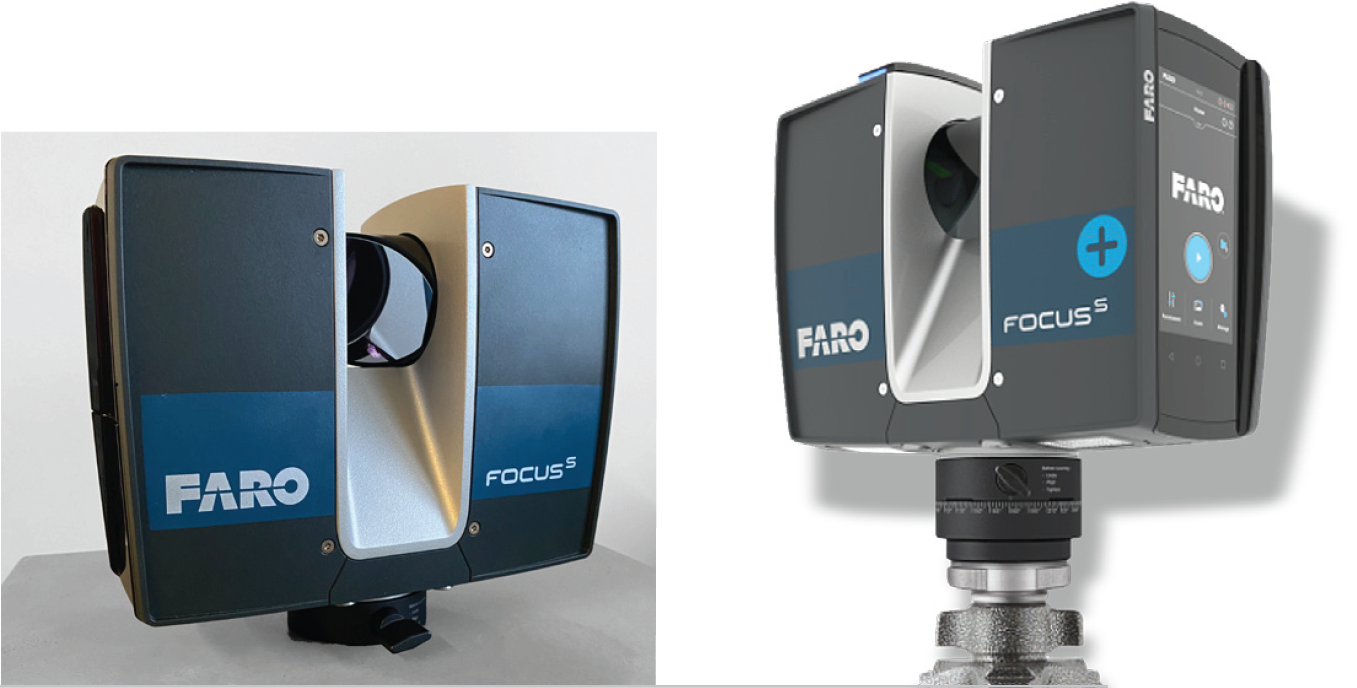

3D Scanning

LINEAR offers 3D scanning services for any machinery, structure, buildings, etc. We use state-of-the-art 3D scanning equipment for accurate representation of the object being scanned. Accuracy within 1mm at 25 meters.

ADDITIONAL SERVICES

ADDITIONAL SERVICES

STOP TIME TESTING

The Linear Service team can accurately measure stop times and safety distances to ensure compliance with local regulations.

VIBRATION TESTING

Linear Automation is capable of doing full machine vibration tests on presses and press equipment.

POWER CONDITION MONITORING

Linear Automation offers power condition monitoring of incoming mains to ensure the safety of your pressroom.