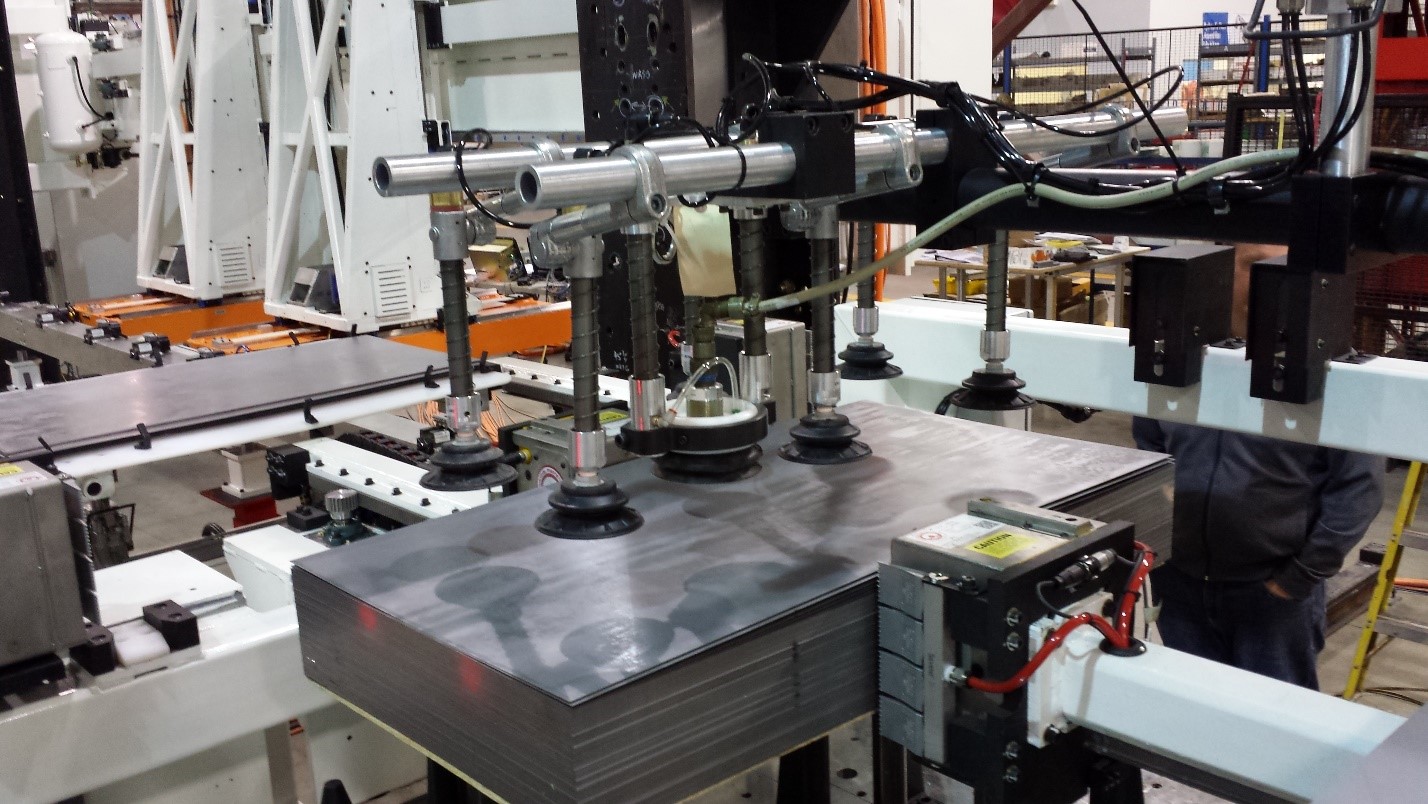

BLANK FEEDING

Linear manufactures a full range of Blank Feed Automation, including magnetic and vacuum conveyors, pick and place, and robotic blank feed systems. Linear’s blank feed systems can be integrated with coil feed systems producing a highly flexible world-class stamping cell.

BLANK FEEDING

Linear manufactures a full range of Blank Feed Automation, including magnetic and vacuum conveyors, pick and place, and robotic blank feed systems. Linear’s blank feed systems can be integrated with coil feed systems producing a highly flexible world-class stamping cell.

BLANK FEEDING

Linear manufactures a full range of Blank Feed Automation, including magnetic and vacuum conveyors, pick and place, and robotic blank feed systems. Linear’s blank feed systems can be integrated with coil feed systems producing a highly flexible world-class stamping cell.

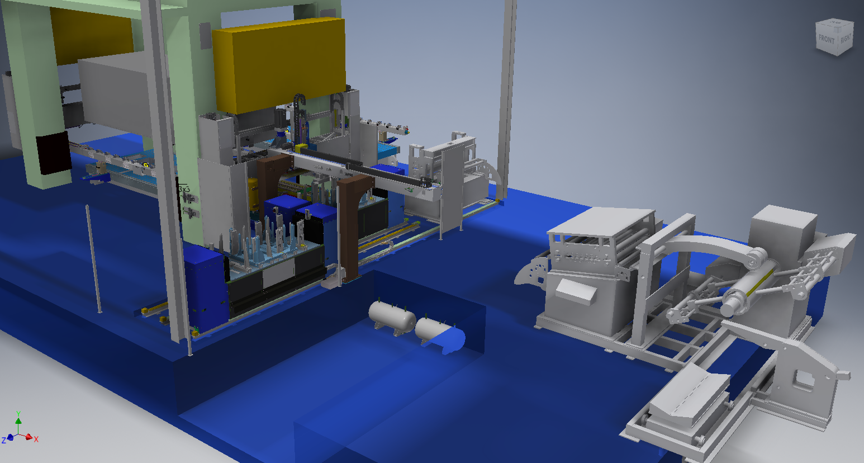

Blank Lubrication Systems

Integration of blank cleaners can be either in-line or off-line, and are 100% programmable for pattern or volume discharge.

Solutions are available for fully automatic mechanical crowding systems, as well as the use of gravity tables.

Blank Orientation Systems

Vision systems or line scanners detect the position of the part and tell the robots how to orient the blanks.

Blank Lubrication Systems

Integration of blank cleaners can be either in-line or off-line, and are 100% programmable for pattern or volume discharge.

Solutions are available for fully automatic mechanical crowding systems, as well as the use of gravity tables.

Blank Orientation Systems

Vision systems or line scanners detect the position of the part and tell the robots how to orient the blanks.

BLANK FEEDING

Linear manufactures a full range of Blank Feed Automation, including magnetic and vacuum conveyors, pick and place, and robotic blank feed systems. Linear’s blank feed systems can be integrated with coil feed systems producing a highly flexible world-class stamping cell.

Blank Lubrication Systems

Integration of blank cleaners can be either in-line or off-line, and are 100% programmable for pattern or volume discharge.

Solutions are available for fully automatic mechanical crowding systems, as well as the use of gravity tables.

Blank Orientation Systems

Vision systems or line scanners detect the position of the part and tell the robots how to orient the blanks.

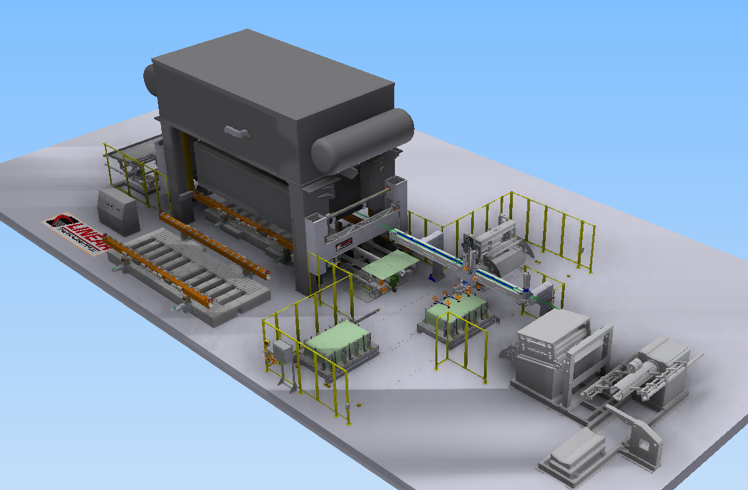

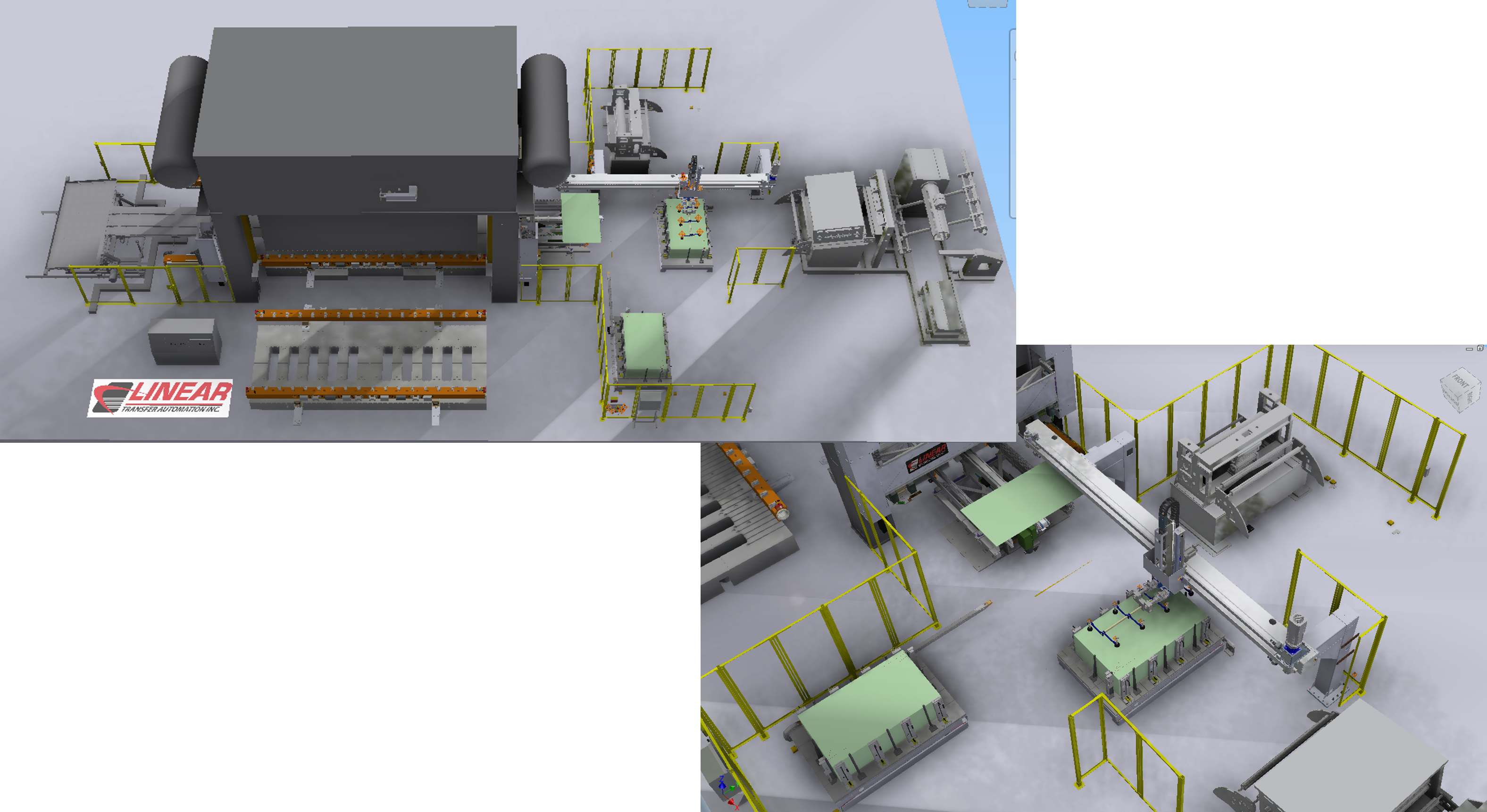

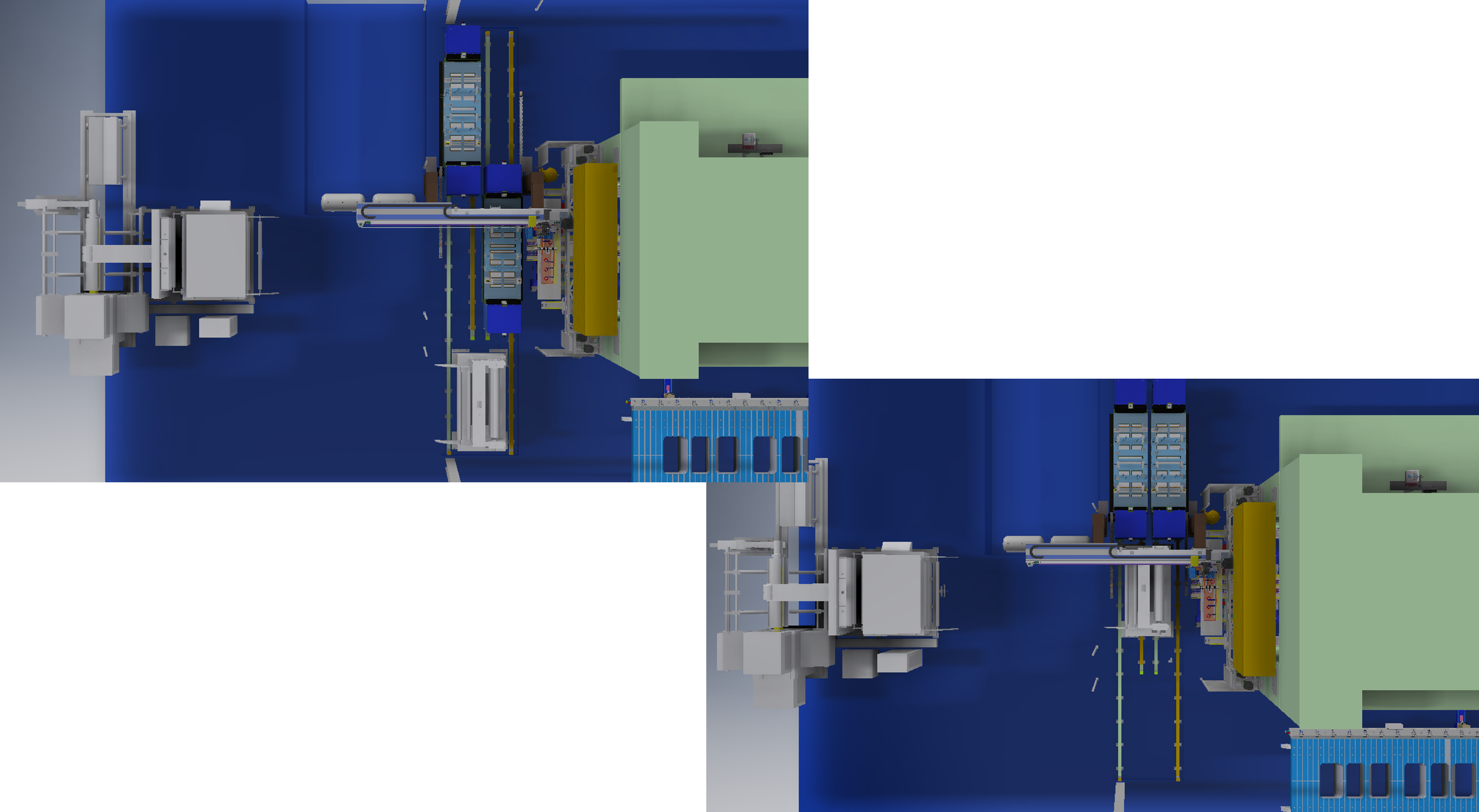

SYSTEMS & CONFIGURATIONS

Full systems for blank handling and blank preparations.

SYSTEMS & CONFIGURATIONS

Full systems for blank handling and blank preparations.

SYSTEMS & CONFIGURATIONS

Full systems for blank handling and blank preparations.

DESTACKING SYSTEMS

- Pick & Place (Single or Dual-head)

- Robotic

- Overhead Magnetic/Vacuum Systems

STACK HANDLING SYSTEMS

-

Stack Carts

- Blank Stack Carts Palletizing Systems

- Stack Orientation Systems

- Hydraulic Pushers, Laser Guidance

- Inground or Above-Ground Stack Lift Systems

DOUBLE BLANK SYSTEMS

-

Contact

- Laser

- Mechanical