FRONT & REAR SERIES

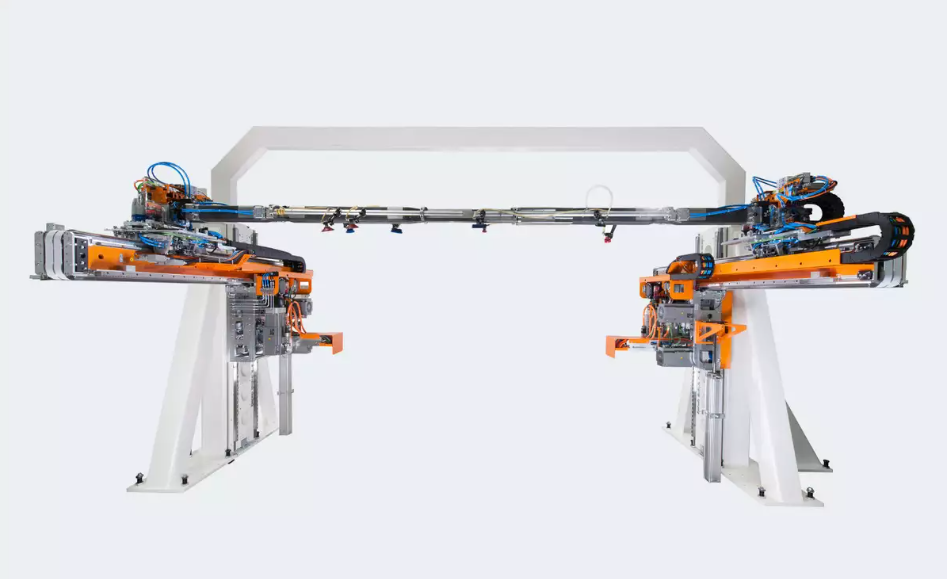

Linear’s Front and Rear Style Transfer is the industry’s most flexible, robust, and versatile transfer automation system. The FR4P Series also allows larger payloads mounting to the front and rear of any press, including those with small or no windows. Servo control of all axes provides high speed, accuracy, and 100% freely programmable strokes.

FRONT & REAR SERIES

Linear’s Front and Rear style transfer is the most flexible, robust, and versatile press automation system in the industry. The FR4P Series also allows for larger payloads mounting to the front and rear of any press, including those with small or no windows. Servo control of all axes provides high speed, accuracy, and 100% freely programmable strokes.

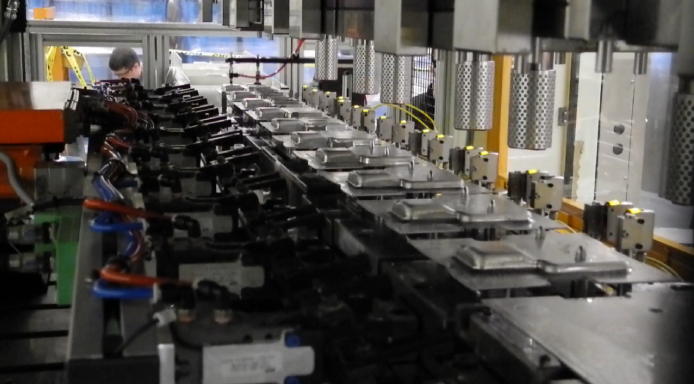

WINDOW MOUNTED SERIES

Linear’s industry-leading Window Mount Transfer Automation (WM) has proven its robustness, reliability, and performance through the decades by utilizing exclusive Linear technology.

WINDOW MOUNTED SERIES

Linear’s industry-leading Window Mount Transfer Automation (WM) has proven its robustness, reliability, and performance through the decades by utilizing exclusive Linear technology.

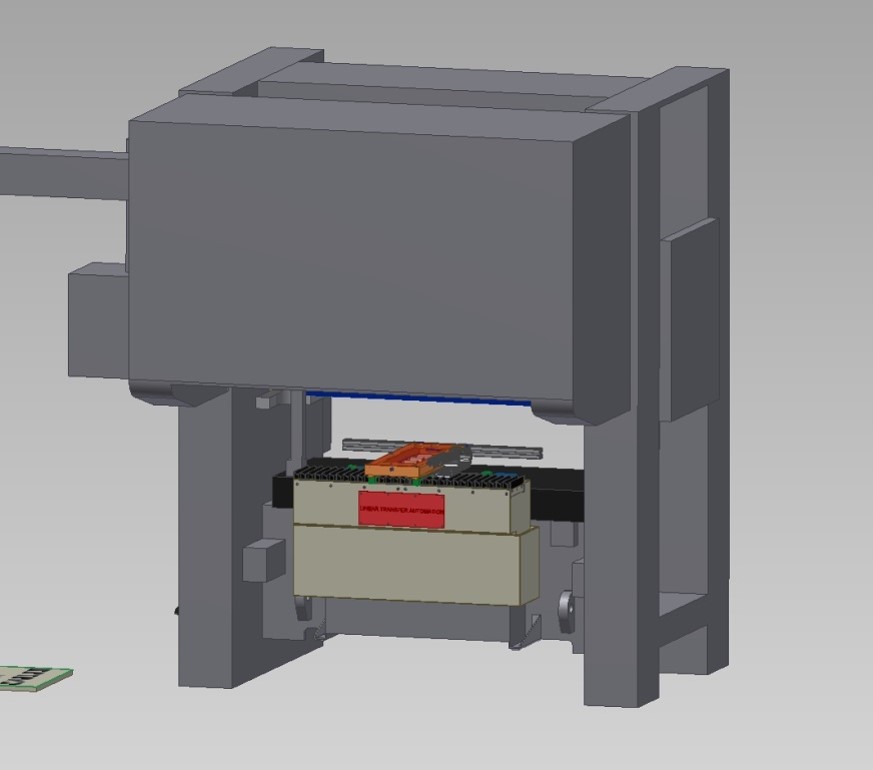

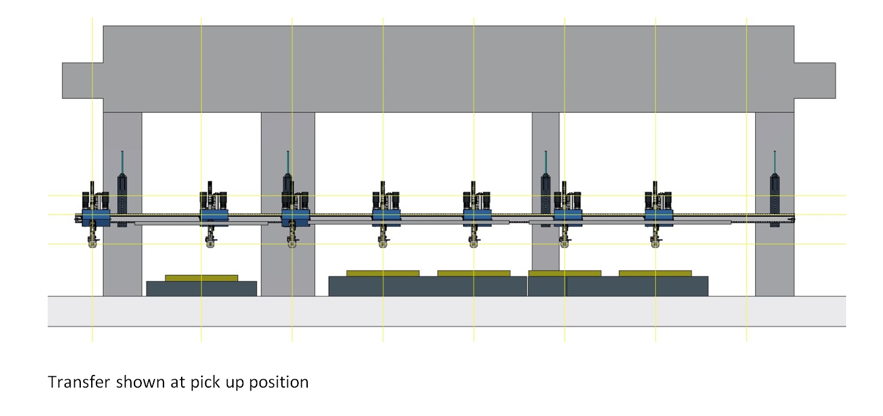

BOLSTER MOUNTED SERIES

The Bolster Mounted Series installs transfer automation directly to the bolster of the press, allowing it to get closer to the tool.

Reduced vibration

One-sided transfer system

Less space utilized

BOLSTER MOUNTED SERIES

The Bolster Mounted series installs directly to the bolster of the press, allowing it to get closer to the tool.

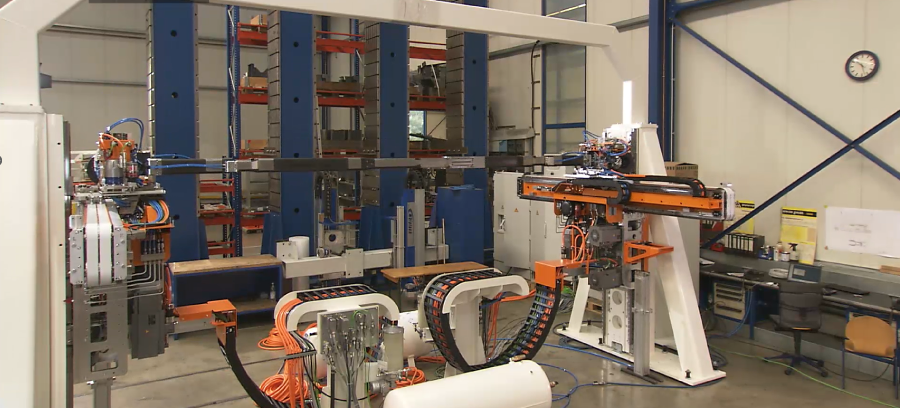

CROSS BAR SERIES

The Crossbar Transfer Automation System for tandem lines uses six degrees of freedom to achieve up to 15 SPM and has a load-bearing capacity of up to 100 kg. It is based on the highly successful Strothmann CompactTransfer system.

CROSS BAR SERIES

This crossbar transfer for tandem lines with six degrees of freedom achieves up to 15 SPM and has a load-bearing capacity of up to 100 kg. It is based on the highly successful Strothmann CompactTransfer system.